Things to consider before you select a ball bearing drawer slide

- Extension

Extension, or "travel", refers to how far the drawer extends from the cabinet.

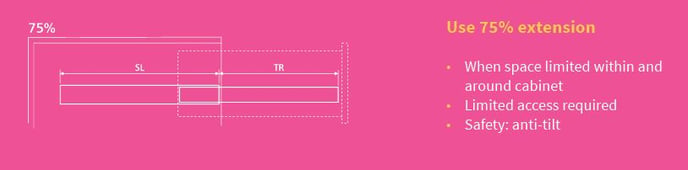

3/4 extension: drawer opens partially, approximately 3/4 of the total slide length:

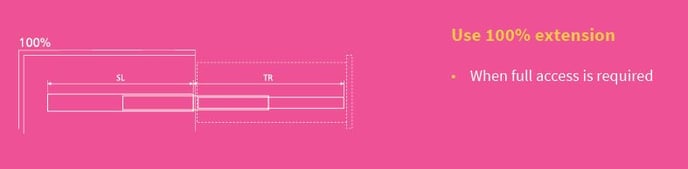

Full extension: drawer opens the same amount as the slide length:

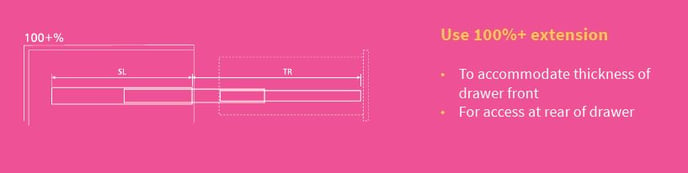

Over travel: drawer opens more than the length of the slide:

Linear motion slides move in a straight line and within the slide’s own length:

- Load Factors

- Cycle rates

All Accuride drawer slides are cycled-tested, depending on the expected frequency for an industry. See the individual product datasheets for details of the cycle rates used for testing.

Our slides are rated for the dynamic (cycled) load that a pair slides mounted 450mm apart can achieve without failure. This load rating decreases proportionally beyond the 450mm length. See the individual datasheets for details of loads for each length of slide.

- Cycle rates

- In all cases, the static (resting) load capacity of each model is at least twice the load rating, providing at minimum, a 100% static safety factor even when the slide is loaded to its maximum rating.

-

- Mounting

For optimal slide performance, mount slides only as indicated in the catalogue or on the technical sheet. Certain slides may be mounted flat under a drawer, but the resulting load rating will be 25% of the quoted load rating.

Mounting slides in different configurations will affect performance and load rating.

- Deflection

Deflection of flat-mounted slides will vary, so we recommend testing to make sure that the deflection is acceptable. - All fixing position must be used to achieve the maximum load rating.

- Remember to include the weight of the actual drawer and expected contents when calculating the load rating required.

- Because slide performance may be affected by factors unique to a specific application, always test slides in your intended application.

- Shock/vibration

Subjecting slides to shock and vibration may adversely affect their performance. Applications that are subject to these conditions should be tested to evaluate the affect on slide performance. If conditions are severe, select a heavier duty slide. - Application factors

When installed in a drawer or cabinet that’s lightweight and flexible, drawer slides can contribute to the structural rigidity of the unit. To ensure that the slide is able to provide this support, select a model with a slightly higher load rating and larger cross-section than you would ordinarily need for the application. - Installation

Most slides are designed to be mounted in pairs on the sides of drawers or the moving unit. When installing the slides, care should be taken to ensure that they are mounted parallel to each other, in vertical and horizontal axes.

Before mounting slides other than as designed, carefully consider any potential adverse effects on the slide and, if necessary, consult Accuride directly.

For example, mounting slides flat under the drawer, rather than on the side, will lower the load rating by at least 75%, but mounting a slide high on one side and low on the other side will have little adverse effect on load rating. Be sure to evaluate the mounting scheme thoroughly and test as needed. Not all slide models may be used in flat-mount applications. - Drawer width and depth

In general, wider drawers require a slide with a higher load rating and a cross section designed to withstand lateral stress. Check with the individual product datasheets or the product reference guide, to see which slides are recommended for particular drawer widths and depth. - Mounting holes

Mounting holes are indicated and dimensioned on product technical sheets. Only those holes shown with a dimension are to be used for mounting. Non-dimensioned holes are tooling holes that often vary in shape and location on slide members. Please refer to 2D CAD drawings for dimensional tolerances. - Length - Slide length is measured as the longest dimension of a fully closed slide. As a rule, always use the maximum length allowable in the application.

- Mounting

Slide length is measured as the longest dimension of a fully closed slide. As a rule, always use the maximum length allowable in the application.

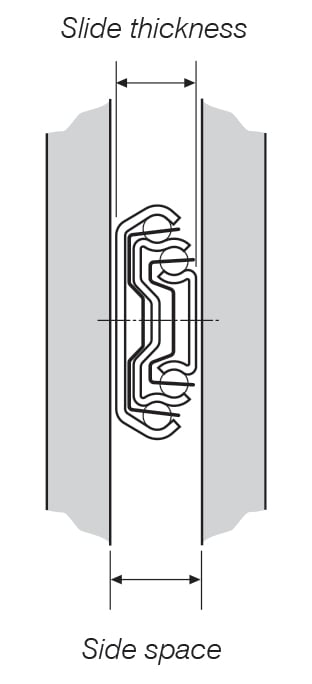

- Side space

Side space is the amount of available room between the drawer side and the cabinet or the chassis and rack.

The correct side space dimension is critical for optimal movement. We recommend allowing between +0.2mm and +0.5mm over the nominal slide thickness. Some slides may need more room, but this will be stated on the individual installation guides.

- Types of Movement

There are generally two types of slide movement:

- Telescoping movement occurring in stages. The drawer member extends fully and then picks up the intermediate member, pulling it to the end of the travel.

- Progressive movement is a result of all slide members moving simultaneously. This type of movement provides extremely smooth, quiet movement.

- Disconnects

The disconnect feature enables you to remove a drawer or drawer member for mounting or general purposes.

Lever disconnect:

Disconnect is achieved by releasing an internal lever and pulling the drawer outward, away from the cabinet.

Push latch:

A latch is pressed to release the drawer. Disconnect is achieved by pulling the drawer firmly though the resistance of the ball retainer.

- Slide Profiles

More than one slide profile (or height) may be appropriate for a given application. Accuride offers several low-profile design options for applications in which a smaller slide profile would enhance the appearance of the completed unit.

- Environmental Factors

Accuride slides are designed for indoor use and should be protected from excessive moisture, chemical fumes, dirt and corrosion. The Accuride self-cleaning ball retainer protects slide raceways by removing foreign particles between ball bearings and the lubricant provided is sufficient for normal slide life.

Use care when applying finishing agents as the overspray may affect slide movement. Should you need to clean the slides, you can re-lubricate them with a quality grease rated "EP" for extreme pressure.

Extreme temperatures can also affect the lubricant and plastic or rubber components. Commercial drawer slides are designed to be used for extended periods in temperatures between -20 and 70 degrees Centigrade.

For service outside normal temperature and humidity ranges, consult Accuride directly.